https://drive.google.com/open?id=1q2sRrmf6T2v1rSAYB40Ki-vvPORGE5US

FDP 101X

My course journal week 1to 3

https://drive.google.com/drive/u/1/folders/1rTh8otT7It5wDBSZauIk8cnE6KUZqIuK

Lecture 1-ANISUR

PARKER SOLAR PROBE

Submit your name and it will be included in a memory card that will fly aboard Parker Solar Probe spacecraft.

Come with us as we plunge through the Sun’s atmosphere, closer to the surface than any spacecraft before it, facing brutal heat and radiation conditions—and ultimately providing humanity with the first-ever close-up view of a star.

Submissions will be accepted through April 27, 2018.

For Sending your Name to the Sun- click the link below

http://parkersolarprobe.jhuapl.edu/The-Mission/Name-to-Sun/

For more information about that go to the below down link here.

FLEXIBLE PAVEMENT DESIGN

NOTE- I

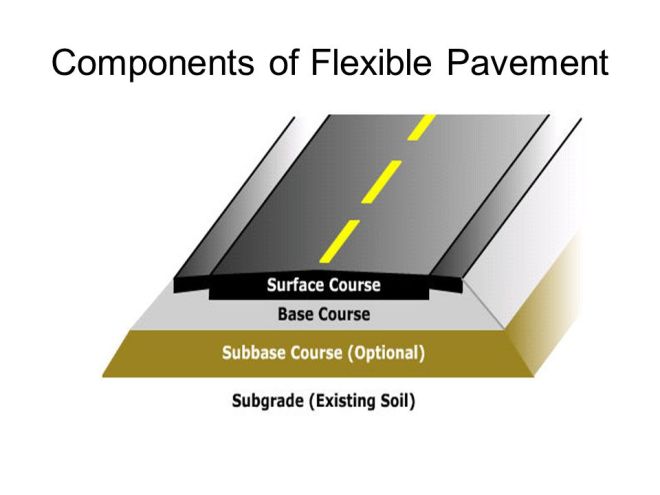

Components:

The Flexible pavement structure consist of number of layers.

The top surface sustain highest magnitude of stress and wear and tear due to moving load (traffic).It has also to withstand the adverse effects of rain fall,flow of surface water.Therefore highest quality of materials are made use of in the top layers.

The components are (from top to bottom)

(i)Prepared soil subgrade

(ii)Granular sub-base cum drainage layer

(iii)Granular base course

(iv)Bituminous binder/surface course

Functions of soil subgrade :

- This is a layer of natural soil from identified borrow pits.

- Thickness 500 mm on NH & SH, 300 mm for rural road.

- Its necessary to keep the subgrade well drained, so that it retain maximum possible strength of the soil to provide adequate support to the pavement structure throughout the year.

Tests for soil subgrade :

a)California Bearing Ratio (CBR) test : – Evaluate the strength of others flexible materials.

b)Dynamics Cone Pentrometer (DCP) :- Strength characteristics of sub-grade soil.

c)Triaxial Compression Test :- Basics strength properties such as cohesion and friction.

d)Plate Bearing Test :- Load supporting capacity of sub-grade and modulas of sub-grade reaction in rigid pavement analysis by westerguard’s approach, determination of elastic modulas of sub-grade.

Functions of Granular Sub-base & Drainage layer

- Serve as a effective drainage layer of the pavement.

- This materials has high permeability with low percentage of fine (less than 5% finner than 0.075 mm)

- In old practice of laying ‘boulder soling’

Functions of Granular Base Course

- Enhance the load carrying capacity of pavements structure .

- This layer sustain wheel load stress and disperses through larger area.

- As per MORTH (Ministry of Road Transport and Highway) the aggregates used low impact value (less than 30%) and low abrasion value (less than 40 %)

Functions of thin Bituminous Surface

- Prevent the entry of surface water into the pavement layer.

- Keep soil sub-grade relatively dry condition & retain stability with good surface and effective drainage , dust free under dry weather.

Functions of thick Bituminous Binder & Surface courses:

- Adopted on stretches of expressway ,NH,SH and others which cater for heavy to very traffic volume with a high proportion of heavy commercial vehicles.

- As per IRC for design the dense bituminous mixes such as Dense Bituminous Macadam(DBM) and Bituminous Concrete(BC)

Introduction of Highway Pavement Design

Objects of Highway Pavement design :

- The surface of the roadway should be stable and non-yielding

- The objective of laying pavements is to support wheel load and transfer the load stresses through wider area

It is always desirable to construct the pavements well above the maximum level of the ground water or the highest water table.

Requirements of Highway Pavements :

Road vehicle able to travel at the design speed without undue discomfort . There are two major requirements –

a) Functional Requirements – road user point of view (good riding quality,less slippery,do not deform surface under wheel load)

b)Structural Requirements- highway engineering point of view(sustain the heavy wheel load and their repeated applications,various design factor related to drainage -climate-environmental)

Types of Pavement Structure :

Based on structural behaviour it is two categories-

a)Flexible pavement

b)Rigid Pavement

Others types of pavements structure include Semi-rigid /composite pavement Pavement,Interlocking Concrete Block Pavement (ICBP)

a) Flexible Pavement :

- Low flexural strength and flexible

- The vertical compressive stress is maximum on the pavement surface , this is decreased at the lower layers.

- Transfer of load here ‘ grain to grain’ for this reason ‘pavement layer system concept’ was develop.

- The top layer to be strongest as the highest compressive stress are to be sustain by this layer in addition to wear and tear.

b) Rigid Pavement :

- High Flexural Strength

- Rigid Pavement generally made of ‘Portand cement concrete’ with or without steel reinforcement at the joint.

- It’s expected to sustain up to 45kg/cm2 of flexural strength

- Rigid pavement has the ‘slab action ‘ and is capable of transmitting the wheel load stresses through a much a wider area below the pavement slab.

Rigid Pavement

Others Types of Pavements :

i) Semi -rigid and composite Pavements:

- Pozzolanic concrete ( lime-flyash-aggregates) or soil cement are used in the sub-base course of the pavement layer.

- Some chemical are form semi rigid layer

- low resistance to impact and abrasion and therfore not used in surface course.

ii) Interlocking cement concrete Block Pavement (ICBP)

- Consist of a layer of cement concrete paver block

- The gap between the paver block are filled with joint filling sand and vibrated so as to provide adequate interlocking between the blocks.

It’s used when pavement is to be constructed in water-logged area or get submerged under water.

Comparison of Flexible and Rigid Pavement :

i) Design Life- a) Design life of flexible pavement is 15 years.

b) Design life of Rigid Pavement is 30 Years.

ii) Curing Period – a) For Flexible it is 24 hours .

b) For Rigid it is 28 days.

iii)Total Thickness – a) Total thickness is higher than Rigid Pavement.

b) Total thickness is less than the Flexible Pavement.

iv)Life Cycle Cost – a) Life cycle cost (Include initial,maintenance,

strengthening)are higher than the Rigid Pavement.

b) Life cycle cost is low.

v) Night Visibility – a) very poor for flexible pavement.

b)Good Night Visibility even under wet condition.